Boris Battery Monitoring System

Boris, what does it do?

The Boris BMS activity consists in measuring, at regular intervals, the Voltage and Temperature of each of the connected batteries. The measurement results are transmitted to the Master Control Unit that takes care of storing the data into a DataBase, displaying the results through a Graphics Web server and generating alarms according to client imposed criteria.

Boris, how does it work?

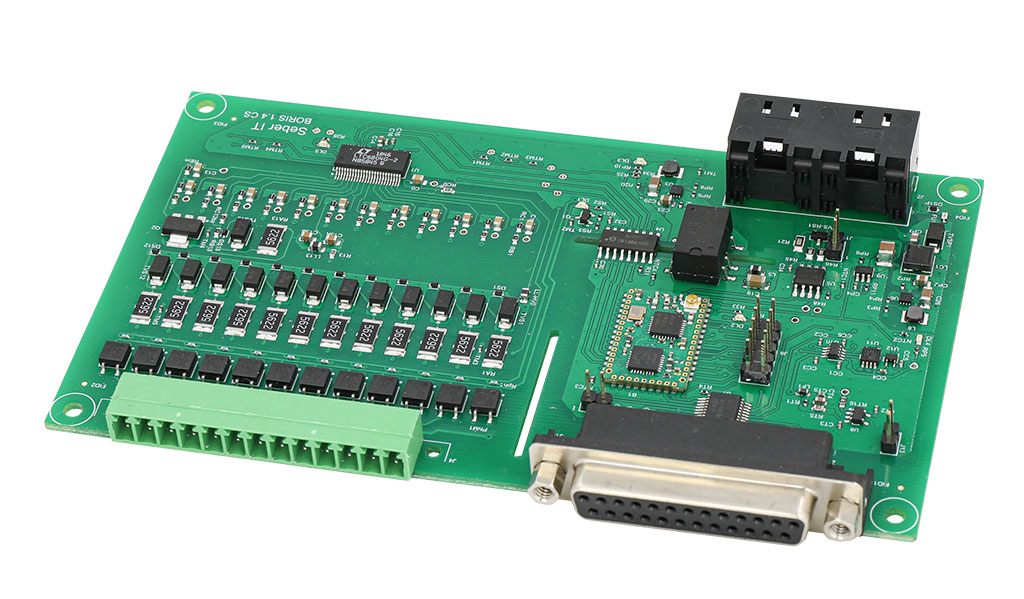

The Boris BMS is based on the Boris 1.42 board, an intelligent device, developed by Seber IT specifically for this task. The board is equipped with Analog/Digital converters and is able to check on no less than twelve in-series connected batteries. An on-board micro-processor (made by using an Acme Systems yarm board) with incorporated application program takes care of the necessary operations and activities in complete independence.

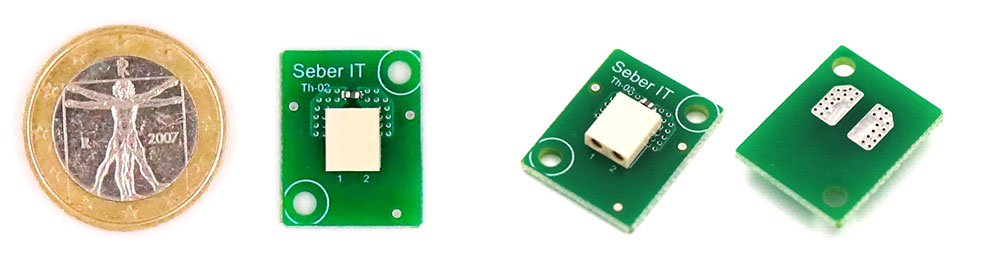

TH02 temperature sensor

The activity of battery monitoring implies measuring the temperature of the battery body at regular intervals. Seber-IT has developed a thermo-sensor specifically for this purpose: Th-02, a small, flat, easy-to-apply mini-PCB to attach to the battery case. It suffices to apply a small piece of bi-adhesive tape or a droplet of glue, p.e. silicon glue, to affix it to the battery body.

The upper-side of the thermo-sensor is equipped with a special poke-in connector for two wires. By just inserting the stripped end of the wire into the connector, a stable class='acmetable' connection will be guaranteed. The underside of the Th-02 has two 'thermo-electrodes', in contact with the battery housing, that 'transmit' the battery body temperature to the sensor element.

Boris Master Control Unit

The BMS also has one Master Control Unit to supervise and coordinate the activities of the connected boards. This unit communicates with the Monitoring Devices through a RS-485 channel or by radio. At user defined intervals, this unit broadcasts a Measurement Request to all connected devices. When the Boris PCB's receive this request, the on-board application engages in the following operations:

- Measurement of potential difference of the connected batteries - Voltage

- Measurement of body temperature of the connected batteries - Temperature

- Data transmission to Master Control Unit - Transmission

The full measurement cycle, from preparation through measurements to data ready for transmission, takes less than one second! And what's more, the measurements are carried out simultaneously on all connected devices. Data transmission is completed within the next few seconds and lasts less than half a second per board.

Links

- Boris board BR142 datasheet https://bms.seberit.com/Boris/EN/EN_DS_Boris_1.42.html

- TH-02 tempertaure sensr datasheet https://bms.seberit.com/Boris/EN/EN_DS_Th-02.html

- Visit the Seber IT web site https://bms.seberit.com/